Introduction to Lion's Mane Mushroom Liquid Culture

Lion's Mane mushroom (Hericium erinaceus) liquid culture represents one of the most efficient and reliable methods for propagating this valuable medicinal and culinary mushroom. Unlike other mushroom propagation techniques, liquid culture allows for rapid mycelium growth in a nutrient-rich solution, creating a versatile inoculum that can be easily transferred to various substrates. For both hobbyist and commercial growers, mastering liquid culture techniques provides significant advantages in terms of colonization speed, contamination resistance, and overall cultivation success.

Liquid culture essentially consists of mushroom mycelium suspended in a nutrient-rich liquid medium, typically containing sugars, nutrients, and sometimes growth stimulants that encourage rapid cellular multiplication. This living suspension of fungal cells creates a "starter culture" that can be used to inoculate grains, sawdust blocks, or other substrates much more quickly and uniformly than traditional methods like spore germination or agar transfers.

What makes liquid culture particularly valuable for Lion's Mane cultivation is how it addresses some of the specific challenges associated with this unique mushroom. Lion's Mane naturally grows at a moderately slow pace compared to more aggressive species like oyster mushrooms, and liquid culture helps accelerate the early growth phases. Additionally, the uniform dispersal of mycelium throughout liquid culture helps ensure even colonization when transferred to substrate, which is particularly important for achieving the distinctive, uniform fruiting pattern that produces high-quality Lion's Mane mushrooms.

This comprehensive guide covers everything you need to know about creating, maintaining, and using Lion's Mane liquid culture, from basic equipment requirements to advanced techniques for optimizing growth and preventing contamination. Whether you're a beginner looking to improve cultivation efficiency or an experienced grower seeking to refine your methods, this guide provides the knowledge needed to successfully work with Lion's Mane liquid culture.

Benefits of Liquid Culture for Lion's Mane Cultivation

Understanding the advantages of liquid culture helps explain why many successful cultivators incorporate this technique into their growing protocols.

Speed and Efficiency Advantages

Liquid culture significantly accelerates the cultivation process:

- Rapid multiplication: Mycelium grows throughout the liquid medium in three dimensions rather than across the two-dimensional surface of agar

- Colonization time reduction: Substrates inoculated with liquid culture typically colonize 30-50% faster than those inoculated with grain spawn

- Even distribution: When injected, liquid culture immediately distributes mycelium throughout the substrate

- Higher success rate: More inoculation points lead to quicker substrate takeover, reducing contamination vulnerability

- Efficient use of cultures: A single agar culture can generate dozens of liquid culture jars

- Resource optimization: Reduces the number of transfers needed to scale up production

- Workflow acceleration: Allows for quicker turnover in cultivation cycles

These efficiency benefits translate directly to higher production capacity with less waiting time.

Contamination Resistance Advantages

Properly prepared liquid culture offers enhanced protection against competitors:

- Sealed environment: Remains in a sealed container until use, reducing exposure to contaminants

- Antibacterial properties: Lion's Mane naturally produces compounds that inhibit certain bacteria

- Visual verification: Contamination is often clearly visible in transparent liquid media

- pH barriers: Optimized acidity levels favor mycelium while discouraging many contaminants

- Selective pressure: The liquid environment can be optimized specifically for Lion's Mane growth

- Quality control opportunity: Allows testing a small sample before using on valuable substrates

- Sugars to acids conversion: As mycelium metabolizes sugars, it creates an environment increasingly favorable to itself

These contamination resistance features are particularly valuable for Lion's Mane, which grows more slowly than some competitor organisms.

Economic Benefits

From a practical perspective, liquid culture offers cost advantages:

- Reduced spawn costs: Create large amounts of inoculum from small starter cultures

- Lower labor requirements: Less time spent on transfers and preparation

- Higher success rates: Fewer failed blocks translates to better return on investment

- Consistent production scheduling: More predictable colonization timelines

- Extended shelf life: Properly stored liquid culture remains viable for months

- Reduced equipment needs: Requires fewer specialized tools than other propagation methods

- Scalability: Easily scaled from hobbyist to commercial production levels

These economic advantages make liquid culture an attractive option for growers at any scale.

Essential Supplies and Equipment

Successful liquid culture work requires specific tools and materials designed to maintain sterility and support mycelial growth.

Basic Equipment Checklist

These fundamental items provide the foundation for creating Lion's Mane liquid culture:

- Pressure cooker/canner: Minimum 15 PSI capability, preferably 15+ quart capacity

- Mason jars: Regular or wide-mouth with metal lids (8oz or 16oz recommended)

- Self-healing injection ports: Silicone or pre-made ports that allow needle entry

- Synthetic filter discs: For gas exchange while maintaining sterility

- Syringe filters: 0.2-0.22 micron for air exchange on jars or for filter-sterilizing solutions

- Syringes and needles: 10-20ml syringes with 16-18 gauge needles for transfers

- Scalpel or X-acto knife: For cutting tissue or agar samples

- Alcohol lamp or torch: For flame sterilization of tools

- Isopropyl alcohol (70%): For surface disinfection

- Parafilm or micropore tape: For sealing plates and cultures

- Digital scale: For precise measurement of media ingredients

- pH meter or pH strips: For checking and adjusting solution acidity

- Still air box or flow hood: For clean work environment during transfers

- Stir plate and stir bar: Optional but helpful for mixing media and growth

Many of these items are available from laboratory supply companies, mushroom cultivation suppliers, or can be adapted from common household items.

Liquid Culture Media Ingredients

The nutrient solution that supports mycelial growth requires specific components:

- Base liquid: Distilled water, avoiding chlorinated tap water

- Primary carbohydrate source: Dextrose, malt extract, honey, light corn syrup, or maple syrup

- Nutritional supplements: Peptone, yeast extract, or nutritional yeast (optional)

- pH buffers: Citric acid, phosphoric acid, or commercial buffers for adjustment

- Mycelium source: Clean culture on agar, liquid culture syringe, or mushroom tissue

- Antibacterial additives: Food-grade hydrogen peroxide or antibiotics (for challenging situations)

- Growth stimulants: Vitamin supplements or mushroom-specific growth enhancers (optional)

- Anticoagulants: Peptone or commercial formulations to prevent clumping (optional)

The quality of these ingredients directly impacts the success of the liquid culture.

Sterilization Equipment

Proper sterilization is critical for liquid culture success:

- Pressure cooker/autoclave: Must reach 15 PSI for effective sterilization

- Heat-resistant gloves: For safely handling hot items

- Autoclave tape: Indicates when proper sterilization temperature has been reached

- Aluminum foil: For covering jar lids during sterilization

- Pressure cooker rack: Keeps jars off direct heat

- Timer: For tracking sterilization duration

- Thermometer: For verifying cooling before inoculation

- Sterilized water: For dilution or adjustments if needed

These items ensure proper sterilization of both equipment and media.

Clean Work Environment Setup

Creating a contamination-free workspace:

- Still air box (SAB): Clear plastic container with arm holes for working in still air

- Laminar flow hood: For professional-level clean air environment (significant investment)

- HEPA air purifier: For cleaning ambient air before work

- UV sterilization lamp: For surface sterilization before work (use with caution)

- Disinfectant spray: For cleaning work surfaces

- Clean room or dedicated space: Separated from household traffic and airflow

- Disposable gloves: For maintaining cleanliness during procedures

- Face mask: To prevent breath contamination

- Hair covering: To prevent contamination from falling hair or dandruff

Investment in clean working conditions significantly improves success rates.

Step-by-Step Liquid Culture Preparation

Following a systematic approach ensures consistent, contamination-free liquid culture production.

Media Formulation for Lion's Mane

Creating the optimal nutrient solution for Lion's Mane mycelium:

- Basic formula: 4% carbohydrate solution (40g sugar source per 1000ml water)

-

Lion's Mane preferred recipe:

- 1000ml distilled water

- 20g light malt extract

- 20g dextrose (or honey/maple syrup alternative)

- 0.5g nutritional yeast (optional)

- pH adjustment: Adjust to 5.5-6.0 pH using food-grade citric acid

- Mixing process: Dissolve ingredients in warm (not hot) water

-

Alternative formulas:

- Simple formula: 40g honey or light corn syrup in 1000ml water

- Enhanced formula: 30g malt extract, 10g dextrose, 1g peptone in 1000ml water

- Considerations for Lion's Mane: This species prefers slightly more complex carbohydrates than some other mushrooms

- Clarity factor: Clear media allows better visual monitoring

- Media quantity: Typically fill jars to 60-70% capacity to allow for shaking

This formulation balances nutrition with clarity for optimal growth and monitoring.

Container Preparation

Properly preparing containers for liquid culture:

- Jar selection: 8oz or 16oz mason jars with metal lids are ideal

-

Lid modification options:

- Two-hole method: Drill two 1/8" holes in metal lid

- One for self-healing injection port

- One for air filter

- Single-port method: One central hole for injection port, use filter syringe for air exchange

-

Injection port installation:

- Silicone RTV method: Apply high-temp silicone over holes

- Pre-made port method: Insert commercial injection ports

- Alternate method: Use a small piece of high-temp silicone with an X cut in center

-

Filter installation:

- Synthetic filter disc secured with silicone

- 0.2 micron syringe filter with silicone or gasket

- Tyvek or micropore tape covering hole (less ideal but functional)

- Testing ports: Ensure injection ports seal after needle removal

- Jar cleaning: Wash thoroughly with soap, rinse well, and allow to dry completely

- Lid preparation: Ensure all modifications are fully cured (silicone typically needs 24+ hours)

- Labeling: Add heat-resistant labels before sterilization

Proper container preparation creates a system that allows inoculation and gas exchange while preventing contamination.

Sterilization Process

Effectively sterilizing liquid culture media:

- Filling jars: Pour prepared media into modified jars, filling to 60-70% capacity

- Lid attachment: Secure lids fingertip-tight only, allowing pressure equalization

- Foil covering: Cover tops with aluminum foil to prevent water intrusion

-

Pressure cooker preparation:

- Add recommended amount of water to cooker

- Place jars on rack (not directly on bottom)

- Ensure jars aren't touching (wrap in cloth if needed)

-

Sterilization parameters:

- Process at 15 PSI for 15-20 minutes for small jars

- 30 minutes for larger volumes

- Begin timing only after reaching full pressure

-

Cooling period:

- Allow pressure cooker to cool naturally

- Never force cool or open under pressure

- Let jars cool to room temperature (8-12 hours, preferably overnight)

- Inspection: Check for any signs of caramelization or darkening

- Storage if not using immediately: Store in clean environment until ready to inoculate

Proper sterilization eliminates competing microorganisms while preserving media quality.

Inoculation Techniques

Transferring mycelium to liquid culture media:

-

Clean environment preparation:

- Disinfect work surface thoroughly

- Set up still air box or turn on flow hood

- Have all tools and supplies ready before starting

-

Personal preparation:

- Wash hands thoroughly

- Wear face mask and gloves

- Secure hair away from work area

-

Tool sterilization:

- Flame sterilize scalpel/knife until red hot

- Allow to cool briefly before use

- Have alcohol lamp or torch accessible

-

Inoculation options:

-

From agar plate:

- Cut 1-2 small wedges of clean, vigorous mycelium

- Transfer quickly to liquid culture jar through briefly opened lid

- Alternately, use syringe to draw small liquid culture through injection port

-

From existing liquid culture:

- Clean syringe and needle with alcohol

- Flame needle until red hot, allow to cool

- Draw 2-3ml from established culture

- Inject into new jar through injection port

-

From tissue sample:

- Select clean internal tissue from fresh mushroom

- Cut 2-3mm cube with sterile scalpel

- Transfer quickly to jar

-

From agar plate:

-

Post-inoculation:

- Secure lid immediately after transfer

- Cover injection site with parafilm or micropore tape

- Label with date and strain information

Clean, quick transfers minimize contamination risk.

Growth and Maintenance of Lion's Mane Liquid Culture

Proper care during development ensures healthy, vigorous liquid culture.

Optimal Growth Conditions

Creating the ideal environment for Lion's Mane liquid culture development:

- Temperature range: 70-75°F (21-24°C) is ideal for Lion's Mane mycelium

- Light exposure: Minimal light is best during development

- Incubation position: Place on stable surface to avoid excessive sloshing

- Air exchange: Ensure filter ports remain unobstructed

- Contamination protection: Keep in clean area away from direct air currents

- Growth timeline: Visible growth typically appears within 3-7 days

- Full colonization: Usually requires 10-14 days total

- Agitation schedule: Gentle swirling every 2-3 days after growth appears

These conditions support vigorous mycelial growth while minimizing contamination risk.

Monitoring for Health and Contamination

Visual assessment of liquid culture development:

-

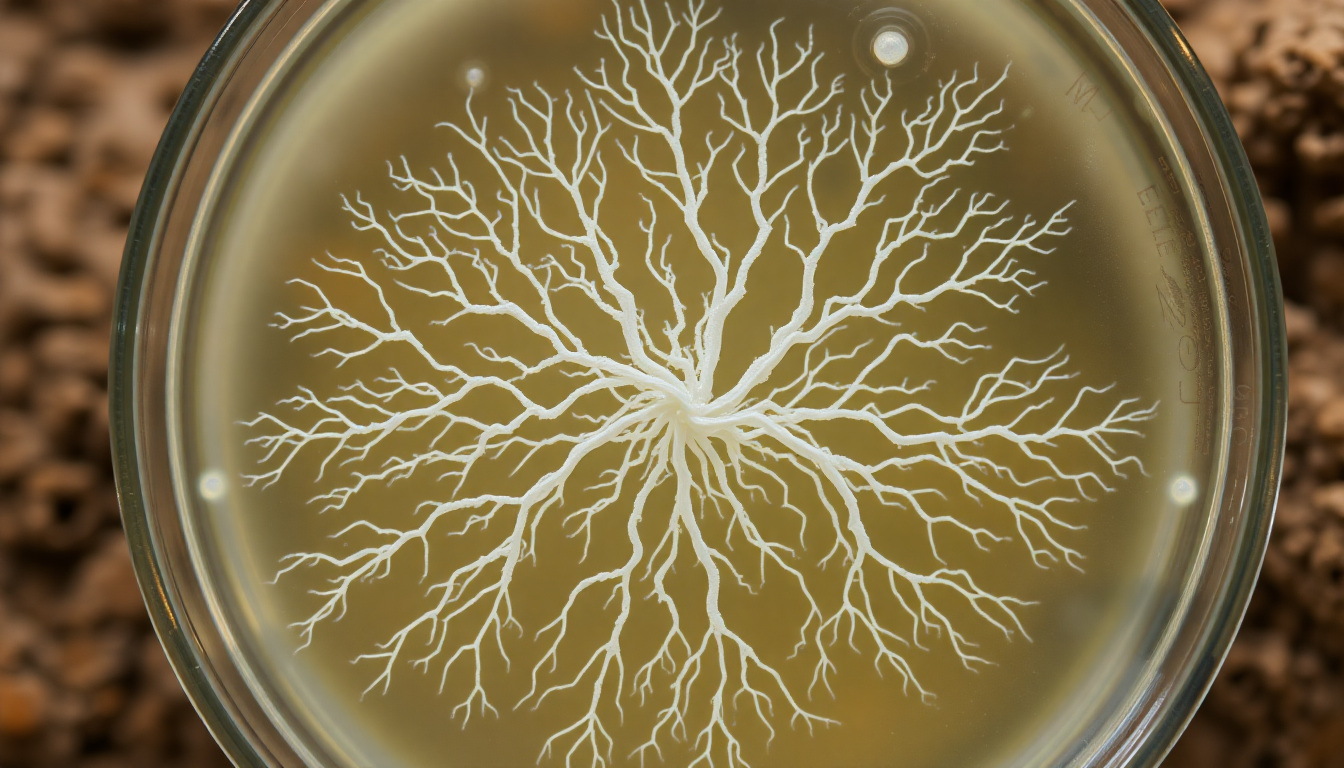

Healthy appearance:

- White, fluffy or cottony growth

- Small to medium-sized mycelial clusters

- Clear to slightly cloudy liquid between clusters

- Sweet, mushroom-like smell when briefly opened

- Gradual increase in cluster size and number

-

Contamination indicators:

- Unusual colors (green, black, pink, orange)

- Slimy or mucous-like appearance

- Foul or sour smell

- Unusual growth patterns or excessive cloudiness

- Gas production or pressure buildup

- Film forming on surface

- Sediment that doesn't incorporate into mycelium

-

Lion's Mane specific characteristics:

- Forms round, pompom-like clusters in liquid

- Growth pattern is typically slower than oyster varieties

- Sometimes produces small primordial formations in liquid

- May develop slight yellowish tint when mature (not contamination)

Regular visual inspection helps catch problems early.

Shaking and Homogenization

Techniques for promoting even growth and preventing clumping:

- Initial period: Allow undisturbed growth for first 3-5 days

- First agitation: Gentle swirling when small clusters appear

- Regular schedule: Gentle shaking every 2-3 days after initial growth

-

Technique importance:

- Avoid vigorous shaking that could damage mycelium

- Aim for gentle break-up of larger clusters

- Ensure all surfaces get exposed to solution

-

Timing considerations:

- Shaking too early can slow initial growth

- Shaking too vigorously can damage sensitive hyphae

- Lion's Mane benefits from more gentle handling than some species

- Signs of readiness: When medium-sized clusters have formed

- Homogenization for usage: More thorough mixing immediately before drawing for inoculation

- Special considerations: Lion's Mane tends to form tighter clusters than other species

Proper agitation promotes healthy development and usability.

Storage and Shelf Life

Maintaining viability of completed liquid cultures:

- Optimal storage temperature: 34-38°F (1-3°C) in refrigerator

- Room temperature viability: Typically 1-2 months at 65-75°F (18-24°C)

- Refrigerated shelf life: 3-6 months when properly stored

- Monitoring during storage: Check periodically for contamination

- Container considerations: Keep original container sealed

- Light exposure: Store in dark conditions

- Position: Store upright to prevent filter saturation

- Revival after refrigeration: Allow to warm to room temperature before use

- Signs of age: Darkening liquid, reduced mycelial vigor, excessive metabolite production

- Rejuvenation: Transfer aging culture to fresh media before complete deterioration

Proper storage extends usability considerably.

Troubleshooting Common Liquid Culture Issues

Even with careful technique, challenges may arise. Here's how to address common problems.

Contamination Identification and Management

Recognizing and addressing unwanted organisms:

-

Bacterial contamination:

- Appearance: Cloudy liquid, slimy texture, often with foul odor

- Cause: Inadequate sterilization, poor inoculation technique

- Prevention: Longer sterilization time, improved sterile technique

- Response: Discard contaminated culture completely

-

Mold contamination:

- Appearance: Colored growth (green, black, gray), often powdery or fuzzy

- Cause: Airborne spores during inoculation, contaminated starter culture

- Prevention: Work in still air box or flow hood, use clean cultures

- Response: Discard immediately to prevent spore spread

-

Yeast contamination:

- Appearance: Bubbly fermentation, yeasty smell, often with white to cream-colored growth

- Cause: Inadequate sterilization, excessive sugar, contaminated tools

- Prevention: Proper sterilization, appropriate sugar levels

- Response: Discard contaminated culture

-

False positives:

- Lion's Mane metabolites: Slightly yellow liquid is normal

- Initial cloudiness: May clear as mycelium develops

- Refraction patterns: Light can create illusions of contamination

Proper identification prevents discarding healthy cultures unnecessarily.

Growth Problems and Solutions

Addressing slow or unusual development:

-

No visible growth after 7 days:

- Possible causes: Poor inoculum, extreme temperatures, antimicrobial agents in water

- Solutions: Check temperature, ensure viable starter culture, verify media formulation

-

Extremely slow growth:

- Possible causes: Low temperatures, nutrient deficiency, pH issues

- Solutions: Increase temperature to 70-75°F, check media recipe, adjust pH if needed

-

Excessive clumping:

- Possible causes: Lack of agitation, high mycelium density, species characteristic

- Solutions: Gentle regular shaking, consider adding peptone to future batches

-

Overly thick growth:

- Possible causes: Excessive nutrients, extended incubation

- Solutions: Use promptly, dilute with sterile water if necessary for injection

-

Stalled growth:

- Possible causes: Contamination, nutrient depletion, pH shift

- Solutions: Check for contamination, transfer to fresh media if needed

Systematic troubleshooting resolves most growth issues.

pH Imbalance Correction

Addressing acidity issues in liquid culture:

- Ideal pH range: 5.5-6.0 for Lion's Mane liquid culture

- Testing methods: pH meter, pH strips (less accurate but functional)

-

Too acidic (below 5.0):

- Symptoms: Slowed growth, smaller clusters

- Adjustment: Add small amounts of sterilized baking soda solution

-

Too alkaline (above 6.5):

- Symptoms: Increased contamination risk, unusual growth patterns

- Adjustment: Add small amounts of sterilized citric acid solution

-

Preventative approach:

- Buffer addition during initial formulation

- Using standardized recipes

- Measuring ingredients precisely

- Testing frequency: Before sterilization and if growth issues occur

- Sterilizing additives: Any pH adjustments must be made with sterile solutions

Proper pH creates an environment favorable to mycelium while discouraging contaminants.

Equipment and Technique Refinement

Improving results through better methods:

-

Pressure cooker issues:

- Problem: Not reaching proper pressure

- Solution: Check gasket, ensure proper water level, verify gauge accuracy

-

Injection port failures:

- Problem: Leaking after injection

- Solution: Use higher quality ports, proper installation technique

-

Filter contamination:

- Problem: Wet filters allowing contamination

- Solution: Use hydrophobic filters, protect from moisture

-

Syringe technique problems:

- Problem: Contamination during transfers

- Solution: Improve flame sterilization, use longer needles, practice technique

-

Media formulation issues:

- Problem: Caramelization or excessive darkening

- Solution: Use lower sugar concentration, shorter sterilization time

-

Work environment improvements:

- Problem: Recurring contamination despite good technique

- Solution: HEPA filtration, dedicated clean space, positive pressure systems

Continuous improvement of technique leads to higher success rates.

Using Lion's Mane Liquid Culture for Inoculation

Properly developed liquid culture provides an efficient inoculum for various substrates.

Preparing Liquid Culture for Use

Steps to take before inoculating substrates:

- Visual inspection: Verify no contamination is present

- Warming: If refrigerated, allow to reach room temperature (1-2 hours)

- Homogenization: Gently shake to break up mycelial clusters

-

Syringe preparation:

- Clean exterior with alcohol

- Flame sterilize needle until red hot

- Allow to cool briefly

-

Drawing technique:

- Insert through injection port

- Withdraw desired amount

- If clogs occur, use larger gauge needle

- Proper mixing: Shake syringe gently to distribute mycelium

- Usage timing: Use within 24 hours of drawing from master culture

- Storage between uses: Keep in clean container, refrigerate if not using immediately

Proper preparation ensures viable, contaminant-free inoculum.

Grain Spawn Inoculation

Using liquid culture to create grain spawn:

-

Spawn container preparation:

- Properly sterilized grain in jars or bags

- Cooled to room temperature

-

Injection site preparation:

- Clean with alcohol wipe

- Allow to dry completely

-

Needle sterilization:

- Flame until red hot

- Allow to cool briefly

-

Inoculation rate:

- 1-3ml per quart jar

- 3-5ml per 2.5lb grain bag

- More for faster colonization, less for economy

-

Injection technique:

- Insert needle through self-healing port

- Distribute liquid in several spots if possible

- Withdraw needle carefully

-

Post-inoculation handling:

- Gently shake to distribute liquid culture

- Label with date and strain information

- Place in incubation environment

-

Expected timeline:

- First visible growth: 3-5 days

- Full colonization: 10-21 days depending on conditions

Liquid culture significantly accelerates grain colonization compared to other methods.

Direct Substrate Inoculation

Bypassing grain spawn by inoculating final substrates directly:

-

Suitable substrates:

- Supplemented sawdust blocks

- Wood-based pellet formulations

- Master's Mix (50% hardwood, 50% soy hulls)

-

Sterilization requirements:

- Complete sterilization essential (not pasteurization)

- Proper cooling before inoculation

-

Inoculation rates:

- 10-20ml per 5lb substrate block

- Higher rates for faster colonization

-

Injection pattern:

- Multiple injection points throughout block

- Evenly spaced for uniform colonization

-

Incubation conditions:

- 70-75°F (21-24°C)

- No light requirement during colonization

-

Colonization expectations:

- First visible growth: 5-7 days

- Full colonization: 14-21 days

- More time required than grain due to substrate density

-

Advantages:

- Eliminates grain spawn step

- Reduces contamination opportunities

- Streamlines production

-

Disadvantages:

- Requires more liquid culture

- Slightly slower than grain spawn method

- Less efficient for large-scale production

Direct inoculation works well for small to medium-scale operations.

Liquid Culture-to-Agar Transfers

Creating new agar cultures from liquid culture:

-

Agar preparation:

- Malt extract agar (MEA) or potato dextrose agar (PDA) work well

- Pour plates and allow to cure properly

-

Liquid culture preparation:

- Homogenize with gentle shaking

- Prepare sterile transfer tools

-

Transfer methods:

-

Syringe method:

- Sterilize needle, place 1-2 drops in center of plate

-

Loop method:

- Dip sterile loop into culture, streak across agar surface

-

Pipette method:

- Use sterile pipette to place small drops on agar

-

Syringe method:

-

Post-transfer handling:

- Seal plates with parafilm

- Incubate at 70-75°F (21-24°C)

- Store in clean environment

-

Growth expectations:

- Initial growth visible in 2-4 days

- Full plate colonization in 7-14 days

-

Sector selection:

- Choose most vigorous, rhizomorphic growth

- Transfer to new plates for strain isolation/improvement

-

Benefits:

- Creates backup cultures

- Allows strain maintenance

- Provides opportunity for strain improvement

Maintaining cultures on agar provides insurance against liquid culture contamination.

Advanced Liquid Culture Techniques

For experienced cultivators, these advanced methods enhance liquid culture performance.

Strain Isolation and Improvement

Selecting and developing superior Lion's Mane strains:

-

Performance criteria selection:

- Growth rate (colonization speed)

- Cluster formation pattern in liquid

- Resistance to bacterial contamination

- Fruiting body characteristics when grown out

- Yield potential

-

Isolation technique:

- Transfer from liquid culture to multiple agar plates

- Select fastest-growing, most rhizomorphic sectors

- Re-transfer selected growth to new plates

- Repeat process 3-4 times for stability

- Test final selection by growing to fruiting

-

Maintenance strategy:

- Keep master cultures on agar slants

- Refrigerate at 34-38°F (1-3°C)

- Transfer to fresh media every 3-6 months

- Maintain multiple backups of promising strains

-

Lion's Mane specific considerations:

- Select for dense, compact mycelium

- Look for distinctive "pom-pom" formation tendency

- Evaluate medicinal compound production if possible

Systematic strain improvement significantly enhances results over time.

Enhancing Liquid Culture Formulations

Advanced media development for optimal growth:

-

Growth stimulants addition:

- Vitamin B complex (1-2 drops per liter)

- Mushroom-specific growth hormones

- Trace mineral supplements

-

Enhanced nutrition:

- Peptone (1-2g/liter) for additional nitrogen

- Complex carbohydrate blends (maltodextrin, brown rice syrup)

- Lion's Mane-specific nutrient blends

-

pH stabilization:

- Phosphate buffer systems for long-term stability

- pH monitoring throughout growth cycle

- Optimizing initial pH based on strain preferences

-

Anticoagulants:

- Addition of peptone (0.5-1g/liter)

- Commercial anticoagulant formulations

- Regular agitation protocols

-

Proprietary additives:

- Commercial liquid culture enhancers

- Specific mushroom growth formulations

- Custom-developed supplements

Refined formulations can increase growth rate by 20-40% and improve vigor.

Scaling Up Production

Methods for larger-scale liquid culture production:

-

Container options:

- Media bottles (250ml-1L)

- Erlenmeyer flasks with specialized closures

- Carboys with modified lids

- Commercial fermentation vessels

-

Sterilization considerations:

- Autoclave capacity limitations

- Fractional sterilization for larger volumes

- Commercial sterilization services

-

Mixing systems:

- Magnetic stir plates and stir bars

- Orbital shakers

- Air-driven mixing systems

-

Aeration options:

- Passive filter systems

- Active aeration through HEPA filters

- Oxygen-enriched environments

-

Harvest techniques:

- Peristaltic pumps for extraction

- Specialized transfer systems

- Batch processing protocols

-

Quality control:

- Regular microscopic examination

- Contamination testing protocols

- Viability assessments

Scaling requires careful planning and investment in appropriate equipment.

Long-term Storage Methods

Preserving cultures for extended periods:

-

Refrigeration protocol:

- Optimal temperature: 34-38°F (1-3°C)

- Storage container considerations

- Regular viability checking

-

Freezing techniques:

- Addition of 10-15% glycerol as cryoprotectant

- Gradual temperature reduction

- Storage at -4°F (-20°C) or colder

- Proper revival procedures

-

Slant storage:

- Transfer to agar slants for long-term storage

- Sealing with parafilm

- Refrigeration of completed slants

-

Water storage method:

- Sterile water storage technique

- Small mycelium pieces in distilled water

- Room temperature viability for 6-12 months

-

Lyophilization (freeze-drying):

- Advanced preservation technique

- Requires specialized equipment

- Provides multi-year storage potential

Proper long-term storage ensures genetic stability and continuous access to valued strains.

Frequently Asked Questions About Lion's Mane Liquid Culture

How long does Lion's Mane liquid culture stay viable?

Lion's Mane liquid culture maintains viability for different periods depending on storage conditions. At room temperature (65-75°F/18-24°C), a properly prepared Lion's Mane liquid culture typically remains viable for 1-2 months, though its vigor may gradually decline after the first month. When refrigerated at 34-38°F (1-3°C), the same culture can remain viable for 3-6 months, with some cultivators reporting success using refrigerated cultures up to 8 months old.

Several factors influence longevity, including the initial media formulation, the culture's health, storage container quality, and temperature stability. Cultures with higher nutrient concentrations generally last longer, as do those stored in containers with effective gas exchange systems. Signs that a liquid culture is losing viability include darkening of the liquid, reduced mycelial density, and unusual metabolite production.

To maximize storage life, refrigerate the culture, minimize temperature fluctuations, keep the container upright to prevent filter saturation, and store away from light. When ready to use stored culture, allow it to warm to room temperature gradually (1-2 hours) before use, and expect slightly longer colonization times with older cultures. For critically important strains, consider refreshing liquid cultures by transferring to fresh media every 2-3 months rather than testing the limits of storage viability.

Why is my Lion's Mane liquid culture turning yellow?

Yellowing in Lion's Mane liquid culture is common and typically not a cause for concern in most cases. This coloration usually results from metabolite production as the mycelium breaks down nutrients and interacts with its environment. Lion's Mane specifically tends to produce yellowish to amber metabolites as cultures mature, which is considered normal and often indicates a healthy, active culture.

Several factors can influence the degree of yellowing:

- Age of the culture (older cultures produce more metabolites)

- Higher nutrition levels in the media (more resources to metabolize)

- Stress factors like temperature fluctuations or pH shifts

- Genetic factors specific to the strain being cultivated

However, it's important to distinguish normal yellowing from contamination. Normal metabolite yellowing appears as a gradual, uniform color change in the liquid, while the mycelium remains white. Contamination typically presents as patchy discoloration, unusual growth patterns, or strong, unpleasant odors.

If the yellowing is accompanied by healthy, white mycelial growth and no unusual odors, the culture is likely fine to use. In fact, some cultivators consider moderate yellowing to be a sign of a vigorous, active culture. If concerned, you can test the culture by inoculating a small amount to agar to verify its purity before using it for larger projects. For future batches, using less nutritive media or harvesting the culture earlier in its development can reduce yellowing if preferred.

How much liquid culture should I use to inoculate grain or substrate?

The optimal amount of Lion's Mane liquid culture for inoculation depends on the volume of substrate, desired colonization speed, and economic considerations. For grain spawn preparation, which serves as an intermediate step before final substrate inoculation:

- Quart jar of grain (approximately 1lb): 1-3ml of liquid culture

- 2.5lb bag of grain: 3-5ml of liquid culture

- 5lb bag of grain: 5-10ml of liquid culture

For direct substrate inoculation, bypassing the grain spawn stage:

- 5lb supplemented sawdust block: 10-20ml of liquid culture

- Small experimental blocks (1-2lb): 3-8ml of liquid culture

- Larger production blocks (10lb+): 20-40ml of liquid culture

Higher inoculation rates generally result in faster colonization and reduced contamination risk, but at increased cost. A good rule of thumb is that doubling the inoculation rate can reduce colonization time by about 30%, but with diminishing returns beyond certain points.

For Lion's Mane specifically, which colonizes somewhat slower than more aggressive species like oyster mushrooms, erring on the side of slightly higher inoculation rates often proves beneficial. Commercial growers typically determine their optimal rates by balancing colonization speed against liquid culture production costs. Beginners are often advised to start with the higher end of the recommended ranges until they gain experience with clean working techniques, as the increased inoculation rate provides some protection against contamination through faster substrate colonization.

How can I tell if my Lion's Mane liquid culture is contaminated?

Detecting contamination in Lion's Mane liquid culture requires careful observation for several key indicators that distinguish unwanted organisms from healthy mycelium. Healthy Lion's Mane liquid culture displays specific characteristics: pure white, fluffy mycelial growth forming round, pompom-like clusters; clear to slightly cloudy liquid between clusters; and a mild, pleasant mushroom scent when briefly opened. The growth pattern should show steady, progressive development of these white clusters.

Contamination signs to watch for include:

- Color abnormalities: Any colors other than white or slight yellowing (green, pink, orange, gray, or black growth indicates molds or bacteria)

- Texture changes: Slimy, mucous-like appearance or stringy strands unlike Lion's Mane's typical pom-pom formations

- Odor: Sour, fermented, rotten, or generally unpleasant smells (healthy culture has a mild, pleasant mushroom scent)

- Growth patterns: Unusual films on the surface, sediment that doesn't incorporate into mycelium, or excessively cloudy liquid

- Gas production: Bubbling, pressure buildup, or bulging lids indicate fermentation from yeast or bacterial contamination

- Discoloration progression: While slight yellowing of the liquid is normal as Lion's Mane cultures mature, rapidly spreading discoloration is concerning

One reliable test involves withdrawing a small sample and examining it on a clean white surface or inoculating it to an agar plate to observe growth patterns. When in doubt, it's safest to discard suspicious cultures, as using contaminated liquid culture will almost certainly lead to failed grows and wasted substrate. Maintaining multiple backup cultures and practicing meticulous sterile technique during preparation significantly reduces contamination risk and ensures continuous access to clean cultures for your cultivation projects.

Can I make Lion's Mane liquid culture from a store-bought mushroom?

Yes, it is possible to create Lion's Mane liquid culture from a fresh, store-bought mushroom, though the process requires careful technique and has a higher contamination risk than starting from a known clean culture. To maximize success with this method:

-

Select the freshest Lion's Mane mushroom available, ideally organic and showing no signs of deterioration.

-

Prepare your liquid culture media and containers following standard sterilization protocols.

-

Create a clean working environment using a still air box or flow hood.

-

Using sterile technique, break open (don't cut) the mushroom to expose interior tissue that hasn't been exposed to air contaminants.

-

With a flame-sterilized scalpel or knife, quickly remove a small piece (2-3mm cube) from deep within the mushroom's interior.

-

Transfer this tissue directly into your prepared liquid culture jar, working quickly to minimize exposure time.

-

Seal the container immediately after transfer.

-

Incubate at 70-75°F (21-24°C) and watch closely for contamination during the first 10-14 days.

This technique has a success rate of approximately 30-50% even with good technique, as store-bought mushrooms often harbor bacteria and other fungi. To improve chances of success, consider first transferring the tissue to several agar plates, which allows you to identify and isolate clean mycelial growth before transferring to liquid culture.

Be aware that commercial varieties may be proprietary strains, and their growth characteristics might differ from wild strains or those specifically selected for home cultivation. Many cultivators find this approach valuable for experimentation and learning, but for reliable production, starting with a verified clean culture from a reputable supplier typically proves more efficient in the long run.

Conclusion

Lion's Mane mushroom liquid culture represents a powerful tool for both beginning and experienced cultivators seeking to optimize their cultivation process. The efficiency, reliability, and flexibility of liquid culture makes it particularly valuable for working with Lion's Mane mushrooms, which benefit from the accelerated colonization and even distribution that this method provides. By mastering the techniques outlined in this guide—from proper media formulation and sterile procedures to advanced methods for strain improvement and storage—cultivators can significantly improve their success rates while reducing time to harvest.

What makes liquid culture particularly valuable in Lion's Mane cultivation is how it addresses some of the specific challenges associated with this unique mushroom. Lion's Mane's moderate growth rate compared to more aggressive species benefits from the head start that liquid culture provides. Additionally, the uniform dispersal of mycelium throughout liquid culture helps ensure even colonization when transferred to substrate, which is particularly important for achieving the distinctive, uniform fruiting pattern that produces high-quality Lion's Mane mushrooms.

As with all cultivation techniques, success with liquid culture comes through practice, careful observation, and continuous refinement of methods. By starting with the fundamentals outlined in this guide and gradually incorporating more advanced techniques as experience grows, cultivators at any level can harness the power of liquid culture to enhance their Lion's Mane mushroom production. Whether growing for personal use, medicinal benefits, or commercial purposes, liquid culture provides a foundation for consistent, contamination-resistant cultivation that maximizes both efficiency and yield.

Share:

Lion’s Mane Mushroom Cocktail: A Bold New Way to Drink Smart

How to Grow Lion’s Mane Mushrooms at Home: A Simple Step-by-Step Guide